3 Images

ID: 177522

Datalogic ID: PD9531-DPMK1

PowerScan PD9531-DPM 2D HD DPM Multi-IF Kit (USB) schwarz gelb

Detailed product title

3 Images

Gross:

incl.

vat.

immediately

Added to cart

Gross:

incl.

vat.

immediately

Discover

Similar products

Discover

Similar products

ID: 153291

Datalogic ID: DBT6400-HC

RIDA DBT6400-HC kabelloser Barcode-Scanner 2D Area Imager Bluetooth 4.0 Weiß/Hellgrün

ID: 248820

Datalogic ID: 943500054

Skorpio X5 Datenerfassungsterminal, 2D, MR, BT, WLAN, NFC, Num., Gun, erw. Akku, Android

ID: 222639

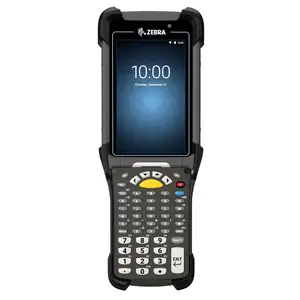

Zebra ID: MC330L-SG3EG4RW

MC3300x Datenerfassungsterminal, 2D, LR, SE4850, BT, WLAN, NFC, Func. Num., GMS, Android

ID: 188024

Zebra ID: MC930B-GSECG4RW

MC9300 Datenerfassungsterminal, 2D, ER, SE4850, BT, WLAN, Func. Num., Gun, IST, Android

ID: 245907

Zebra ID: DS2208-SR00007ZZWW

DS2208 - Barcode-Scanner - Handgerät - 2D-Imager 762 mm / Sek. decodiert Schnittstellenkabel erforderlich